Weber Portal - welcome to your Weber world.

We make your life even easier – and information about your machines quickly, easily and individually accessible. Use our online portal: here you are provided with exclusive online functions 24/7 on 365 days a year. Profit from quick and uncomplicated access to all line documentation as well as our service support. Know what is running. And how it is running.

Talk to your production line.

Our Digital Factory Solutions serve as a general interface for providing process data and connecting to the outside world. With the latest cloud technology, you can view and document data on your Weber line and the process in which it is integrated from anywhere 24 hours a day, 365 days a year: relevant key figures, performance, availability, maintenance or error messages can be called up and managed at any time. On request, the Digital Factory Solutions can be expanded with many other Weber products and can therefore be adapted to your needs.

- Easy and quick overview of current production data in real time to make fundamental decisions - anywhere where you have access to the internet

- With the most important KPIs in real time, deviations from the optimum can be easily recognized and corrected immediately

- With the line and machine analysis, you can easily identify bottlenecks in your production and take necessary action

- By storing all batches, you always know how you have produced in the past and can therefore predict future productions

- One application for all machines: irrelevant if this is a Weber or third-party machine

- Easy exchange of information between the operator at the machine, the shift supervisor, the technical department or the warehouse

- Perfect interaction between FactoryCockpt and FactoryAssist. Deviations detected by the shift supervisor in FactoryCockpit can be immediately transmitted to the operator and recommendations for action are given

- Quick and easy troubleshooting on the machine by the operator with solutions suggested for each fault

- By including own solutions in an error/solution database, the knowledge of all employees is archived and made available to all employees in the company

- One application for all maintenance tasks - irrelevant if this is a Weber or third-party machine

- Organization of your own company hierarchy with locations, departments, lines and machines

- Documents, photos, images and videos can easily be added to any maintenance

- Recurring maintenance work are re-planned automatically to ensure nothing can be forgotten

- FactoryCare runs on every mobile device

- All maintenance work carried out are archived, including documents and test reports added

One software, many possibilities.

Do you want to view the operating data of your system at any time? Or access live data directly on the machine? With our browser-based software Weber@net, calling up and evaluation of operating data is carried out directly on the machine.

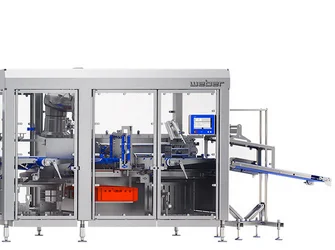

Machine operation thought smart.

The Weber OneControl user interface combines attractive design, process-oriented operating concept and intuitive navigation using modern touchscreen technology. And enables intuitive operation and monitoring of the complex slicing and inserting lines. Operation is via a multi-touch screen that responds to interactions such as swipe and gesture control. Language has been avoided in the design as far as possible, and more use has been made of easily understandable graphic elements. In this way, you can quickly get an overview of all relevant processes on the system.