Company History

-

Weber Maschinenbau becomes Weber Food Technology

Effective January 1, 2024, Weber Maschinenbau will become Weber Food Technology GmbH. This will make the company’s identity directly apparent in its name. As part of the renaming, the TEXTOR brand, which has been the marketing name for slicers and other line components, will be integrated into Weber.

2024 -

Preparation is everything – and efficient as never before with the Weber wePRESS

More output, more yield, even higher automation, continuous production: particularly uneven natural products such as streaky bacon, baked bacon, raw ham and fresh meat can be perfectly shaped with the wePRESS, thus ensuring a more economical production.

-

40 years of Weber

40 years of innovation. 40 years of passion. Weber Maschinenbau celebrates its 40th anniversary and looks back on a unique success story from a small meat processing company in central Hesse to a globally successful solution provider for complete slicing and packaging lines.

2021 -

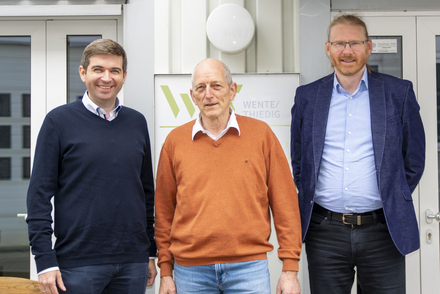

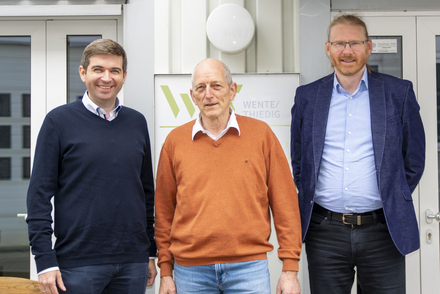

Wente/Thiedig GmbH integrated completely into the Weber Group

Following the majority shareholding since 2015, Wente/Thiedig GmbH was fully integrated into the Weber Group in 2021. The company in Braunschweig develops camera and image processing systems that are, for example, used in optical scales and scanners of the slicer. The integration in the Weber product range strengthens the potential for further innovations in the scanning technology sector.

-

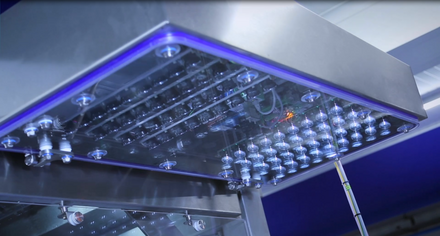

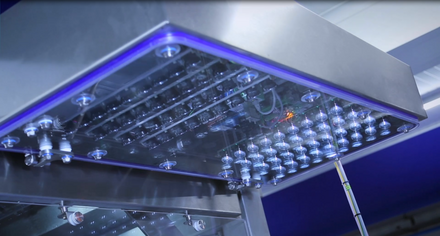

Weber launches SprayTech

With the innovative and sustainable spraying technology for interleaver applications or for extending the minimum shelf life, Weber launched a technology for more sustainability through less film consumption and more food product safety.

-

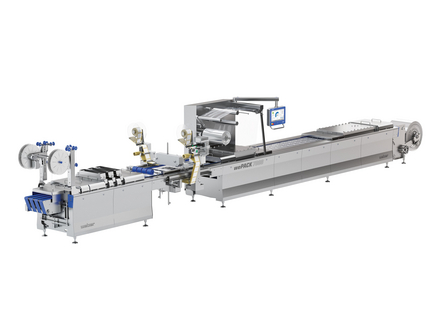

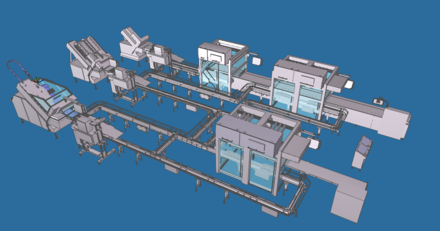

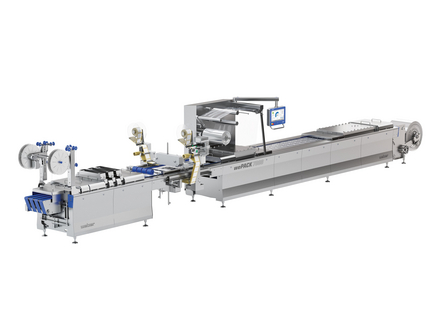

Weber becomes a packaging technology supplier

With wePACK, Weber launches the first thermoformer and becomes a complete line solution provider. From preparation of the product to the tested primary packaging, we offer everything from one source. Through this unique initial situation, we are able to take the integration of slicers, automation, packaging and end-of-line equipment to a new level.

2019 -

360° service with Weber Guardian

With Weber Guardian Weber introduces a comprehensive smart-service-program in 2018 – for maximum performance along the entire production line. Weber Guardian covers versatile solutions and products in the areas of service, parts, upgrades as well as training and is therefore an all-round carefree package for Weber’s customers.

-

Groundbreaking ceremony for the Weber packaging center

With a groundbreaking ceremony the construction work for the new Weber Maschinenbau plant startet. In Werther, an office building and a workshop with a total area of around 6,000 square meters are being built. In the future, components as well as forming/sealing dies and cutting tools for thermoforming packaging machines will be manufactured here.

-

Slicing. Packaging. Weber.

Due to the merger with a renowned packaging machine manufacturer, thermoformers have been added to the portfolio of the Weber Group. Weber is now able to offer integrated and highly automated system solutions for cold cuts, from slicing to packaging, all from a single source.

-

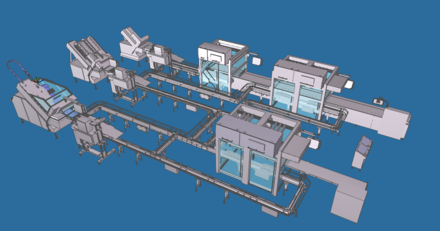

Novel transport system WSS presented at IFFA

The innovative Weber Shuttle System (WSS) sets new standards in food production. WSS transports single portions gently and precisely to one or more stations. As an intelligent workpiece carrier the system is flexibly expandable: from simple entry solutions to high-end lines for complex infrastructures (as a standalone solution or coupled with existing Weber slicers). Using the WSS, several packaging machines can be fed via one slicer.

2016 -

Latest Skinner development focuses on sensor technology

With the ASD 460 Weber launches a fully automatic defatting machine for backs, chops, loins and loins with ribs. Thanks to a camera-supported, fully automatic detection of fat layers and programmable controlled movement along longitudinal profile, the Skinner achieves a productivity of up to 1,200 pieces per hour. The machine's processing quality is so good that time-consuming manual trimming is reduced to a minimum.

-

Weber to remain a family-owned company

Owner Guenther Weber has transferred shares in the company to his sons Tobias Weber and Hubertus Weber, making them co-partners in Weber Maschinenbau GmbH. Tobias Weber has been working for the company since 2009 and heads the application technology department. Hubertus Weber is currently studying physics at the Technical University of Berlin. Guenther Weber retires from active business.

2015 -

Weber Maschinenbau welcomes 1000th employee

Samuel Pfister was recruited as the 1000th employee, accepting a traineeship with hopes of becoming a construction mechanic.

2014 -

Weber Power Control wins award

The new Weber Power Control user interface was honoured with the renowned Red Dot Award in the category Communication Design.

-

Slicing and automatic picking of fresh meat

Thanks to the commitment of Weber`s application department it was possible for the first time to slice precise weight portions of fresh meat – for example steak – with a Weber slicer, and to portion and infeed it automatically with a pick & place robot into a package.

-

TEXTOR

Founding of the TEXTOR Maschinenbau GmbH in Wolfertschwenden, Germany. The product range includes „smart & easy“ machines, for customers with individual application areas providing technological alternatives to the Weber portfolio.

2011 -

Full flexibility without performance limitations

With the quadruple Pick Robot Weber presents the latest developments in food robotics at IFFA, the most important show of the industry. The Pick Robot works fully automatically and with highest precision. An integrated camera system detects the position of portions so that the system can correct the position if necessary.

2010 -

Grand opening Weber, Inc.

Weber celebrates the grand opening of our “North American Technology Center” in Kansas City, Missouri. It is intended to provide our customers with improved access to product testing and demonstration, parts inventory and training classes at Weber U(niversity). In recognition of Weber Maschinenbau's significant investments in the North American economy, the mayor of Kansas City, Kay Barnes, has proclaimed that from now on “Weber Day” will be officially celebrated there on June 23.

-

25 years of Weber Maschinenbau

In recognition of our silver anniversary worldwide, Guenther Weber was honored this spring to have a street in Breidenbach, Germany, renamed to commemorate his contributions to the region and his worldwide achievements.

2006 -

Foundations for blade factory are laid

Weber opens a third manufacturing facility in Gross Nemerow, Germany. What was initially used as an assembly plant for derinding machines is now the production site for Weber’s blade technology.

2005 -

Technology evolution continues

Weber´s unbeatable design team sets new standards by introducing the “intelligent” scanner, capable of using two cameras and a laser array to “map” the content of any product for efficient slicing and portion control.

2003 -

Weber grows and grows

The completion of our Neubrandenburg manufacturing facility was perfectly timed to meet exploding worldwide demand. Today, Neubrandenburg is the largest Weber production site.

2000 -

Machine learning in mechanical engineering – Weber's first optical scale

Weber´s revolutionary vision-powered slicing system was another big leap in technology. Designed to visually measure and instantly adjust portions based on the voids in Swiss cheese, the system is also capable of analyzing and adjusting slices based on fat-to-lean ratios on meat.

1998 -

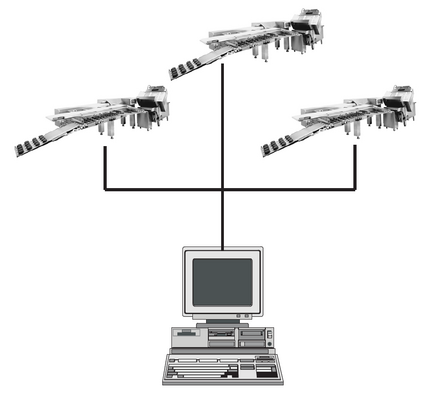

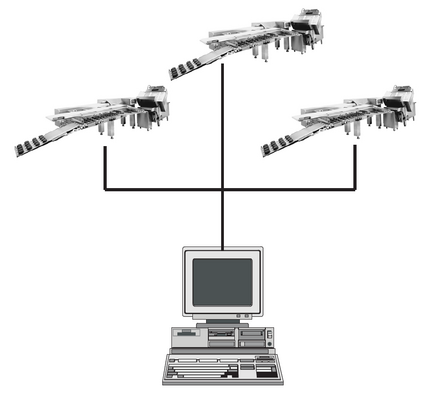

Industry 4.0 at Weber begins: Machines become networkable

Two revolutionary developments at the same time have found their way into Weber: from now on it is possible to reset mean value information on all weights of the running charge across the entire production line – from the final checkweigher back to the slicer. In addition, the first open Weber data interface is put into operation.

-

Turntable for party trays

Introduction of the turntable for the presentation form round shingled (party tray), designed for a customer application.

Weber sells Slicer #500.

1995 -

Weber begins the slicing revolution

CCS 7000, Weber´s first slicing system, resulted from three years of intensive research, development and design investment. Revolutionary in its hygienic design and all-stainless construction, this servo-controlled system featured greater slicing capacity than any other machine on the market.

1986 -

Full speed ahead

Weber´s beginnings were well-timed to take advantage of the early days of IFFA, the international tradeshow that is now our industry´s largest machinery showcase.

1983

-

Digital Factory Solutions: clever solutions for digitized production

Direct access to important key figures, central contact point for data analysis and information procurement, maintenance and servicing tasks at a glance, possibility of communication and knowledge management in production: the digital Weber products FactoryCockpit, FactoryCare and FactoryAssist create more transparency and increase efficiency in the production of food processing companies.

-

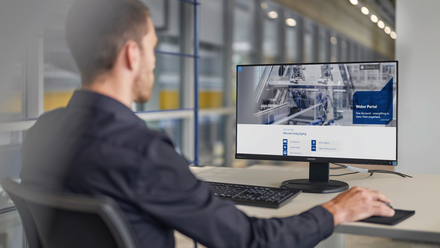

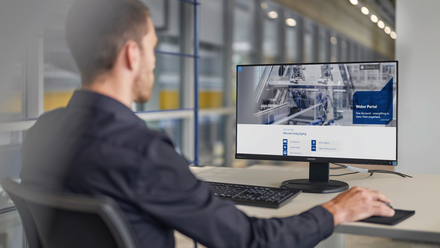

Weber Portal: Welcome to your digital Weber world!

All relevant information and services are available at a glance and around the clock: acting as an introduction to the world of Weber, the portal offers customers direct access to many useful functions and the option of navigating to other Weber platforms, such as the training courses and e-learning programs, for example.

2022 -

we GO GREEN

Weber sets itself the clear goal of CO2-neutral production. To achieve this goal, Weber relies on innovations for sustainable technologies and manufacturing processes, and lives

the quest of sustainability throughout the entire company. -

Growth through digitization and automation

At the location in Neubrandenburg, Germany, one of the worlds most modern sheet metal automation systems has been inaugurated. With a total length of 60 meters and height of 6.95 meters, the automation system disposes over a storage capacity of 840 tonnes. In addition, it reduces the laser standstill time by 30%, the bending process time by 40% and thus increases production significantly.

-

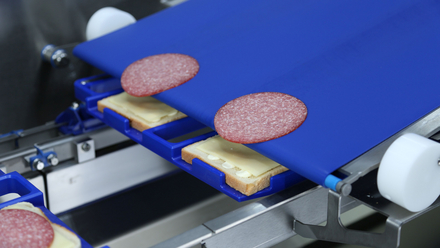

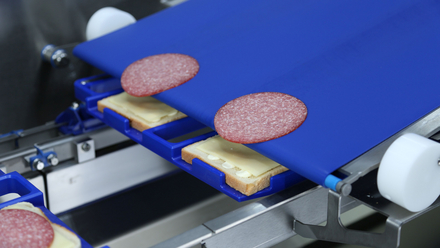

Establishment in the Ready Meal area

With the wePICK and weSHUTTLE automation solutions, Weber has established itself in the Ready Meal and Snacks & Conveniences business sectors. The options when topping and conveying pizzas, sandwiches and baguettes is therefore unlimited.

2020 -

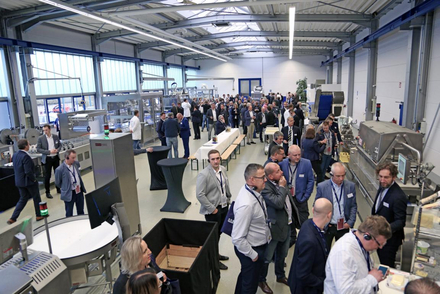

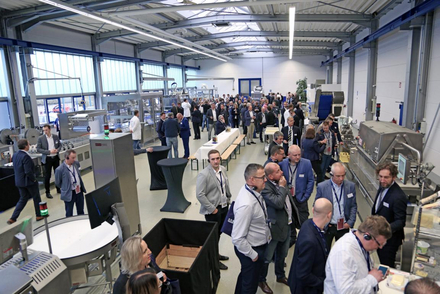

Weber Innovation Days: Welcoming the World to Breidenbach

For the second time, the Weber Innovation Days offered a unique forum consisting of expert lectures, industry dialogue and live presentations. This time the focus was on innovations and line solutions for the efficient processing of bacon and raw ham. More than 300 Weber customers and partners answered the system provider’s call to its headquarters in Breidenbach.

-

AR supports Weber field service

Augmented Reality (AR) glasses support the Weber service staff in their work. These serve as modern remote diagnostics and make it easier for colleagues to work together at any distance: no matter where the service technician is, Weber's colleagues on site can also take a look at the machine and thus contribute to troubleshooting, for example.

-

Tobias Weber becomes CEO

Since 01/01/2018, Tobias Weber holds the position of Chief Executive Officer (CEO) at Weber Maschinenbau. Thus, he is assuming overall responsibility within the Weber Group. Tobias Weber has been a member of the management board since June 2016.

2018 -

Weber Cheese Innovation Days

In November the first Weber Innovation Days took place. For three days it was all about cheese at Weber Maschinenbau and, in particular, how it can be processed as profitably and intelligently as possible. Over 200 guests from all over the world responded the invitation to Breidenbach and were inspired by a varied program of lectures, machine demonstrations and partner exhibitions.

2017 -

Weber invests in sensor technology development

The merger with the longtime development partner Wente/Thiedig GmbH reinforces the potential for the next generation innovations in the area of scan technology. The company, based in Braunschweig, Germany, has long supplied Weber with camera and image processing systems for use in optic weighers and scanners for slicers and pick robots.

-

New insights with the digital twin

Augmented Reality and Virtual Reality enable three-dimensional insights into the interior of individual machines and even entire lines. The applications are manifold: the virtual, but still realistic representation can improve efficiency and availability, replace costly prototypes or eliminate errors by a digital simulation before the machine has been built.

-

Automated production system in Gross Nemerow

In the course of a substantial investment in a new production line consisting of five milling machines, Weber now makes use of a robot at its Gross Nemerow site. The robot is able to control several machines and to equip them with parts without any human intervention. Thus, production can continue fully automated and unmanned – even during rather unpopular night and weekend shifts.

-

First online shop for spare parts

Weber customers can now order Durablade circular and involute blades conveniently and quickly via an online shop.

2013 -

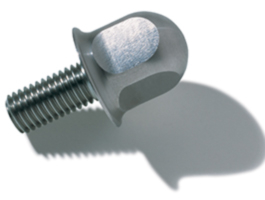

Durablade®

Weber now distributes its own blades under the trade mark „Durablade®“. Weber customers get high quality, long lasting circular or involute blades made out of stainless steel for an attractive price. Besides the usual order channels – like phone, email or fax – the customers can also place an order at the web shop.

-

Used components in Breidenbach

Under the slogan „As Good as New“, Weber offers used and completely overhauled components and even entire lines for further use. This project has its own hall at Weber where a team is refurbishing used slicers and modules. Thus we can guarantee our customers to receive second-hand machines at the highest level of quality.

2012 -

Manager Magazine: "Weber is world market leader"

We all have supposed it for a long time, but the final acknowledgement just came out in 2010: The renowned German ”Manager Magazine” puts Weber on its list of the "1,000 German world market leaders".

-

Automation becomes flexible

Weber presents the Weber Pick Robot at the IFFA in Frankfurt. It offers opportunities for individual and versatile applications in the food industry and can be changed over at the touch of a button. The space-saving systems solve complex tasks like creating various presentation forms and precisely feeding into packages and onto sandwiches.

2007 -

Quadruple interleaver

The anniversary year brings even two technological highlights: Slicer 304 is now expandable to a complete system including weighing machine and interleaver. Also, top class slicer 904 now comes with optional quadruple interleaver to satisfy our customer’s demands.

-

Weber Highlight Slicer 904

Model 904 – the world´s most powerful, productive and hygienic slicing system – kicked off the newest generation of Weber slicers, incorporating everything we have learned about slicing technology in our 25 years of business.

Weber sells slicer #2500.

-

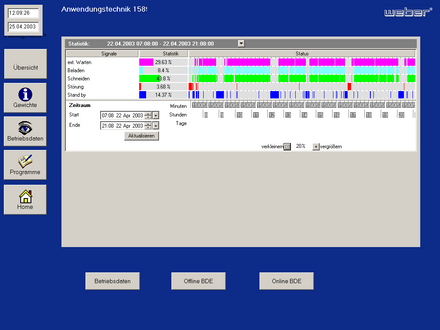

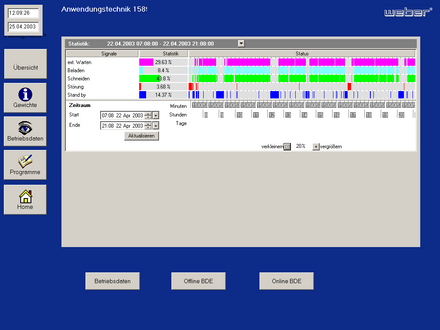

Weber@net is born – new appearance of the data interface

The Weber@net software enables the display and evaluation of various production data directly at the machine. Among many others, the state of line activity, statistics based on ratios and indices, the availability of Slicers and modules can be displayed.

2004 -

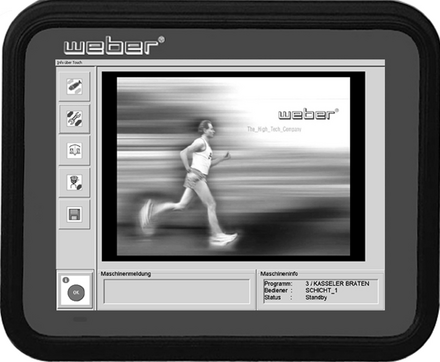

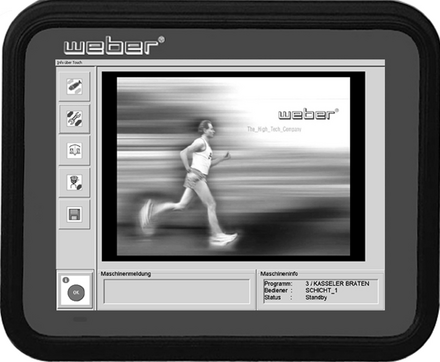

Touch operation is the new standard

Weber revolutionizes machine operation with the introduction of touch technology.

2001 -

Leadership in food safety

The introduction of Weber´s mid-sized model 602 heralded a new generation of Weber hygienic designs, further raising the bar on our well established position of leadership in sanitary operation and clean up ease. Since then every element of every machine design has been re-examined with critical eye.

Even the smallest parts that we design and manufacture internally have been carefully formed to eliminate potential problems and meet the stringent standards exclusive to all Weber machinery.

1999 -

Cheese, please ...

Introducing the superior interleaver in 1997 extended Weber´s reach to a new market of cheese processor. At the same time, new presentation options are made available for customers in the meat processing business.

Weber sells Slicer #1000.

1997 -

Weber establishes the first international subsidiary

Norbert Muehlich sets up the first Weber sales and service office in Kansas City. Since Weber is accepted as the gold standard of slicing technology, North American processors were given expanded access.

1996 -

Weber is a pioneer for automation solutions

Automatic loading of sliced products into packaging machines was another Weber innovation, helping our customers to boost productivity while reducing their labor costs and human contact with processed products.

Weber sells Slicer #100.

1990 -

Weber Derinders

Early Weber derinders could enthuse our meat processing customers with their faster performance, greater worker safety and unmatched reliability. Skinner ASB 1000 was among the first Weber solutions brought to market.

-

The journey begins …

January 2, 1981 Guenther Weber signed the articles of incorporation founding Weber Maschinenbau in Breidenbach, Germany. Expanded several times, the original plant in Breidenbach remains our corporate headquarters.

1981

-

Weber Maschinenbau becomes Weber Food Technology

Effective January 1, 2024, Weber Maschinenbau will become Weber Food Technology GmbH. This will make the company’s identity directly apparent in its name. As part of the renaming, the TEXTOR brand, which has been the marketing name for slicers and other line components, will be integrated into Weber.

2024 -

Digital Factory Solutions: clever solutions for digitized production

Direct access to important key figures, central contact point for data analysis and information procurement, maintenance and servicing tasks at a glance, possibility of communication and knowledge management in production: the digital Weber products FactoryCockpit, FactoryCare and FactoryAssist create more transparency and increase efficiency in the production of food processing companies.

-

Preparation is everything – and efficient as never before with the Weber wePRESS

More output, more yield, even higher automation, continuous production: particularly uneven natural products such as streaky bacon, baked bacon, raw ham and fresh meat can be perfectly shaped with the wePRESS, thus ensuring a more economical production.

-

Weber Portal: Welcome to your digital Weber world!

All relevant information and services are available at a glance and around the clock: acting as an introduction to the world of Weber, the portal offers customers direct access to many useful functions and the option of navigating to other Weber platforms, such as the training courses and e-learning programs, for example.

2022 -

40 years of Weber

40 years of innovation. 40 years of passion. Weber Maschinenbau celebrates its 40th anniversary and looks back on a unique success story from a small meat processing company in central Hesse to a globally successful solution provider for complete slicing and packaging lines.

2021 -

we GO GREEN

Weber sets itself the clear goal of CO2-neutral production. To achieve this goal, Weber relies on innovations for sustainable technologies and manufacturing processes, and lives

the quest of sustainability throughout the entire company. -

Wente/Thiedig GmbH integrated completely into the Weber Group

Following the majority shareholding since 2015, Wente/Thiedig GmbH was fully integrated into the Weber Group in 2021. The company in Braunschweig develops camera and image processing systems that are, for example, used in optical scales and scanners of the slicer. The integration in the Weber product range strengthens the potential for further innovations in the scanning technology sector.

-

Growth through digitization and automation

At the location in Neubrandenburg, Germany, one of the worlds most modern sheet metal automation systems has been inaugurated. With a total length of 60 meters and height of 6.95 meters, the automation system disposes over a storage capacity of 840 tonnes. In addition, it reduces the laser standstill time by 30%, the bending process time by 40% and thus increases production significantly.

-

Weber launches SprayTech

With the innovative and sustainable spraying technology for interleaver applications or for extending the minimum shelf life, Weber launched a technology for more sustainability through less film consumption and more food product safety.

-

Establishment in the Ready Meal area

With the wePICK and weSHUTTLE automation solutions, Weber has established itself in the Ready Meal and Snacks & Conveniences business sectors. The options when topping and conveying pizzas, sandwiches and baguettes is therefore unlimited.

2020 -

Weber becomes a packaging technology supplier

With wePACK, Weber launches the first thermoformer and becomes a complete line solution provider. From preparation of the product to the tested primary packaging, we offer everything from one source. Through this unique initial situation, we are able to take the integration of slicers, automation, packaging and end-of-line equipment to a new level.

2019 -

Weber Innovation Days: Welcoming the World to Breidenbach

For the second time, the Weber Innovation Days offered a unique forum consisting of expert lectures, industry dialogue and live presentations. This time the focus was on innovations and line solutions for the efficient processing of bacon and raw ham. More than 300 Weber customers and partners answered the system provider’s call to its headquarters in Breidenbach.

-

360° service with Weber Guardian

With Weber Guardian Weber introduces a comprehensive smart-service-program in 2018 – for maximum performance along the entire production line. Weber Guardian covers versatile solutions and products in the areas of service, parts, upgrades as well as training and is therefore an all-round carefree package for Weber’s customers.

-

AR supports Weber field service

Augmented Reality (AR) glasses support the Weber service staff in their work. These serve as modern remote diagnostics and make it easier for colleagues to work together at any distance: no matter where the service technician is, Weber's colleagues on site can also take a look at the machine and thus contribute to troubleshooting, for example.

-

Groundbreaking ceremony for the Weber packaging center

With a groundbreaking ceremony the construction work for the new Weber Maschinenbau plant startet. In Werther, an office building and a workshop with a total area of around 6,000 square meters are being built. In the future, components as well as forming/sealing dies and cutting tools for thermoforming packaging machines will be manufactured here.

-

Tobias Weber becomes CEO

Since 01/01/2018, Tobias Weber holds the position of Chief Executive Officer (CEO) at Weber Maschinenbau. Thus, he is assuming overall responsibility within the Weber Group. Tobias Weber has been a member of the management board since June 2016.

2018 -

Slicing. Packaging. Weber.

Due to the merger with a renowned packaging machine manufacturer, thermoformers have been added to the portfolio of the Weber Group. Weber is now able to offer integrated and highly automated system solutions for cold cuts, from slicing to packaging, all from a single source.

-

Weber Cheese Innovation Days

In November the first Weber Innovation Days took place. For three days it was all about cheese at Weber Maschinenbau and, in particular, how it can be processed as profitably and intelligently as possible. Over 200 guests from all over the world responded the invitation to Breidenbach and were inspired by a varied program of lectures, machine demonstrations and partner exhibitions.

2017 -

Novel transport system WSS presented at IFFA

The innovative Weber Shuttle System (WSS) sets new standards in food production. WSS transports single portions gently and precisely to one or more stations. As an intelligent workpiece carrier the system is flexibly expandable: from simple entry solutions to high-end lines for complex infrastructures (as a standalone solution or coupled with existing Weber slicers). Using the WSS, several packaging machines can be fed via one slicer.

2016 -

Weber invests in sensor technology development

The merger with the longtime development partner Wente/Thiedig GmbH reinforces the potential for the next generation innovations in the area of scan technology. The company, based in Braunschweig, Germany, has long supplied Weber with camera and image processing systems for use in optic weighers and scanners for slicers and pick robots.

-

Latest Skinner development focuses on sensor technology

With the ASD 460 Weber launches a fully automatic defatting machine for backs, chops, loins and loins with ribs. Thanks to a camera-supported, fully automatic detection of fat layers and programmable controlled movement along longitudinal profile, the Skinner achieves a productivity of up to 1,200 pieces per hour. The machine's processing quality is so good that time-consuming manual trimming is reduced to a minimum.

-

New insights with the digital twin

Augmented Reality and Virtual Reality enable three-dimensional insights into the interior of individual machines and even entire lines. The applications are manifold: the virtual, but still realistic representation can improve efficiency and availability, replace costly prototypes or eliminate errors by a digital simulation before the machine has been built.

-

Weber to remain a family-owned company

Owner Guenther Weber has transferred shares in the company to his sons Tobias Weber and Hubertus Weber, making them co-partners in Weber Maschinenbau GmbH. Tobias Weber has been working for the company since 2009 and heads the application technology department. Hubertus Weber is currently studying physics at the Technical University of Berlin. Guenther Weber retires from active business.

2015 -

Automated production system in Gross Nemerow

In the course of a substantial investment in a new production line consisting of five milling machines, Weber now makes use of a robot at its Gross Nemerow site. The robot is able to control several machines and to equip them with parts without any human intervention. Thus, production can continue fully automated and unmanned – even during rather unpopular night and weekend shifts.

-

Weber Maschinenbau welcomes 1000th employee

Samuel Pfister was recruited as the 1000th employee, accepting a traineeship with hopes of becoming a construction mechanic.

2014 -

First online shop for spare parts

Weber customers can now order Durablade circular and involute blades conveniently and quickly via an online shop.

2013 -

Weber Power Control wins award

The new Weber Power Control user interface was honoured with the renowned Red Dot Award in the category Communication Design.

-

Durablade®

Weber now distributes its own blades under the trade mark „Durablade®“. Weber customers get high quality, long lasting circular or involute blades made out of stainless steel for an attractive price. Besides the usual order channels – like phone, email or fax – the customers can also place an order at the web shop.

-

Slicing and automatic picking of fresh meat

Thanks to the commitment of Weber`s application department it was possible for the first time to slice precise weight portions of fresh meat – for example steak – with a Weber slicer, and to portion and infeed it automatically with a pick & place robot into a package.

-

Used components in Breidenbach

Under the slogan „As Good as New“, Weber offers used and completely overhauled components and even entire lines for further use. This project has its own hall at Weber where a team is refurbishing used slicers and modules. Thus we can guarantee our customers to receive second-hand machines at the highest level of quality.

2012 -

TEXTOR

Founding of the TEXTOR Maschinenbau GmbH in Wolfertschwenden, Germany. The product range includes „smart & easy“ machines, for customers with individual application areas providing technological alternatives to the Weber portfolio.

2011 -

Manager Magazine: "Weber is world market leader"

We all have supposed it for a long time, but the final acknowledgement just came out in 2010: The renowned German ”Manager Magazine” puts Weber on its list of the "1,000 German world market leaders".

-

Full flexibility without performance limitations

With the quadruple Pick Robot Weber presents the latest developments in food robotics at IFFA, the most important show of the industry. The Pick Robot works fully automatically and with highest precision. An integrated camera system detects the position of portions so that the system can correct the position if necessary.

2010 -

Automation becomes flexible

Weber presents the Weber Pick Robot at the IFFA in Frankfurt. It offers opportunities for individual and versatile applications in the food industry and can be changed over at the touch of a button. The space-saving systems solve complex tasks like creating various presentation forms and precisely feeding into packages and onto sandwiches.

2007 -

Grand opening Weber, Inc.

Weber celebrates the grand opening of our “North American Technology Center” in Kansas City, Missouri. It is intended to provide our customers with improved access to product testing and demonstration, parts inventory and training classes at Weber U(niversity). In recognition of Weber Maschinenbau's significant investments in the North American economy, the mayor of Kansas City, Kay Barnes, has proclaimed that from now on “Weber Day” will be officially celebrated there on June 23.

-

Quadruple interleaver

The anniversary year brings even two technological highlights: Slicer 304 is now expandable to a complete system including weighing machine and interleaver. Also, top class slicer 904 now comes with optional quadruple interleaver to satisfy our customer’s demands.

-

25 years of Weber Maschinenbau

In recognition of our silver anniversary worldwide, Guenther Weber was honored this spring to have a street in Breidenbach, Germany, renamed to commemorate his contributions to the region and his worldwide achievements.

2006 -

Weber Highlight Slicer 904

Model 904 – the world´s most powerful, productive and hygienic slicing system – kicked off the newest generation of Weber slicers, incorporating everything we have learned about slicing technology in our 25 years of business.

Weber sells slicer #2500.

-

Foundations for blade factory are laid

Weber opens a third manufacturing facility in Gross Nemerow, Germany. What was initially used as an assembly plant for derinding machines is now the production site for Weber’s blade technology.

2005 -

Weber@net is born – new appearance of the data interface

The Weber@net software enables the display and evaluation of various production data directly at the machine. Among many others, the state of line activity, statistics based on ratios and indices, the availability of Slicers and modules can be displayed.

2004 -

Technology evolution continues

Weber´s unbeatable design team sets new standards by introducing the “intelligent” scanner, capable of using two cameras and a laser array to “map” the content of any product for efficient slicing and portion control.

2003 -

Touch operation is the new standard

Weber revolutionizes machine operation with the introduction of touch technology.

2001 -

Weber grows and grows

The completion of our Neubrandenburg manufacturing facility was perfectly timed to meet exploding worldwide demand. Today, Neubrandenburg is the largest Weber production site.

2000 -

Leadership in food safety

The introduction of Weber´s mid-sized model 602 heralded a new generation of Weber hygienic designs, further raising the bar on our well established position of leadership in sanitary operation and clean up ease. Since then every element of every machine design has been re-examined with critical eye.

Even the smallest parts that we design and manufacture internally have been carefully formed to eliminate potential problems and meet the stringent standards exclusive to all Weber machinery.

1999 -

Machine learning in mechanical engineering – Weber's first optical scale

Weber´s revolutionary vision-powered slicing system was another big leap in technology. Designed to visually measure and instantly adjust portions based on the voids in Swiss cheese, the system is also capable of analyzing and adjusting slices based on fat-to-lean ratios on meat.

1998 -

Cheese, please ...

Introducing the superior interleaver in 1997 extended Weber´s reach to a new market of cheese processor. At the same time, new presentation options are made available for customers in the meat processing business.

Weber sells Slicer #1000.

1997 -

Industry 4.0 at Weber begins: Machines become networkable

Two revolutionary developments at the same time have found their way into Weber: from now on it is possible to reset mean value information on all weights of the running charge across the entire production line – from the final checkweigher back to the slicer. In addition, the first open Weber data interface is put into operation.

-

Weber establishes the first international subsidiary

Norbert Muehlich sets up the first Weber sales and service office in Kansas City. Since Weber is accepted as the gold standard of slicing technology, North American processors were given expanded access.

1996 -

Turntable for party trays

Introduction of the turntable for the presentation form round shingled (party tray), designed for a customer application.

Weber sells Slicer #500.

1995 -

Weber is a pioneer for automation solutions

Automatic loading of sliced products into packaging machines was another Weber innovation, helping our customers to boost productivity while reducing their labor costs and human contact with processed products.

Weber sells Slicer #100.

1990 -

Weber begins the slicing revolution

CCS 7000, Weber´s first slicing system, resulted from three years of intensive research, development and design investment. Revolutionary in its hygienic design and all-stainless construction, this servo-controlled system featured greater slicing capacity than any other machine on the market.

1986 -

Weber Derinders

Early Weber derinders could enthuse our meat processing customers with their faster performance, greater worker safety and unmatched reliability. Skinner ASB 1000 was among the first Weber solutions brought to market.

-

Full speed ahead

Weber´s beginnings were well-timed to take advantage of the early days of IFFA, the international tradeshow that is now our industry´s largest machinery showcase.

1983 -

The journey begins …

January 2, 1981 Guenther Weber signed the articles of incorporation founding Weber Maschinenbau in Breidenbach, Germany. Expanded several times, the original plant in Breidenbach remains our corporate headquarters.

1981